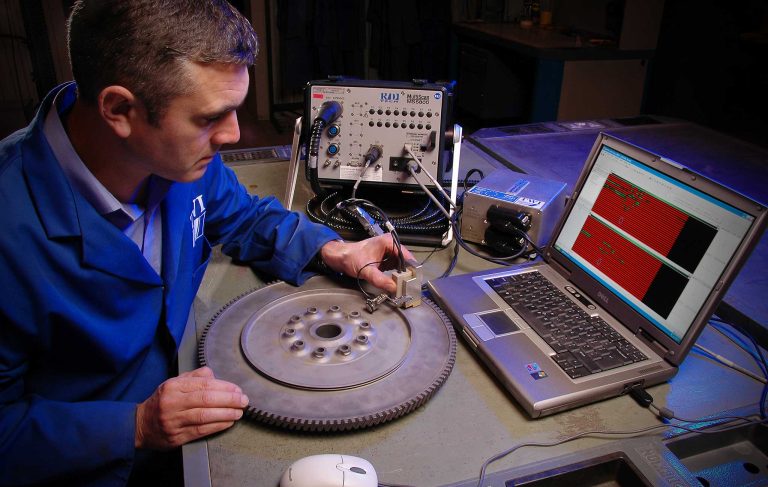

Eddy Current Testing (ECT)

Eddy current testing (ECT) is an electromagnetic nondestructive testing (NDT) method which uses an alternating current passed through a coil in order to create an alternating magnetic field which intern is used to induce a localized current (eddy current) into the test object. Discontinuities such as fatigue cracks will interrupt the flow of eddy currents and alter the terminal impedance of the test coil. The amplitude and phase of the received signal can be interpreted to ascertain the severity and exact location of any discontinuities found.

Eddy current testing applications include the examination of welds, measure conductivity, grain size, hardness, and thickness; to identify materials with different composition, microstructure, magnetic permeability, and condition of heat treatment; and to determine the thickness of coatings and plating on various materials. Eddy current is routinely used to inspect a wide range of different materials and components across several fields of engineering including oil and gas, nuclear, power generation and aerospace.

Eddy Current Testing Level I Course:

This training program was developed to instruct students on the fundamental basics of Eddy Current Testing principles and theory. Students will be instructed in electromagnetic/AC field measurement theory, probe types, probe selection, probe software, operating applications, detection scanning, signal interpretation and equipment and theory utilized in aerospace, petrochemical, structural and pressure vessel applications.

This is a 40-hour course which satisfies the training hours needed for Level I certification in accordance with SNT-TC-1A, ANSI/ASNT CP-189, and NAS-410.

Please call for scheduling before completing purchase of course. 218-851-8347

Eddy Current Testing Level II Course:

This training program was developed to instruct students on the advanced theory, and application of eddy current testing. Course content includes topics such as variables affecting the alternating current, coil impedance, and depth of penetration ,signal-to-noise ratio, test frequency selection, coupling, selection of field strength instrument design considerations, and operating procedures.

This is a 40-hour course which satisfies the training hours needed for Level II certification in accordance with SNT-TC-1A, ANSI/ASNT CP-189, and NAS-410.

Please call for scheduling before completing purchase of course. 218-851-8347