The Education Employers Want For $8,000

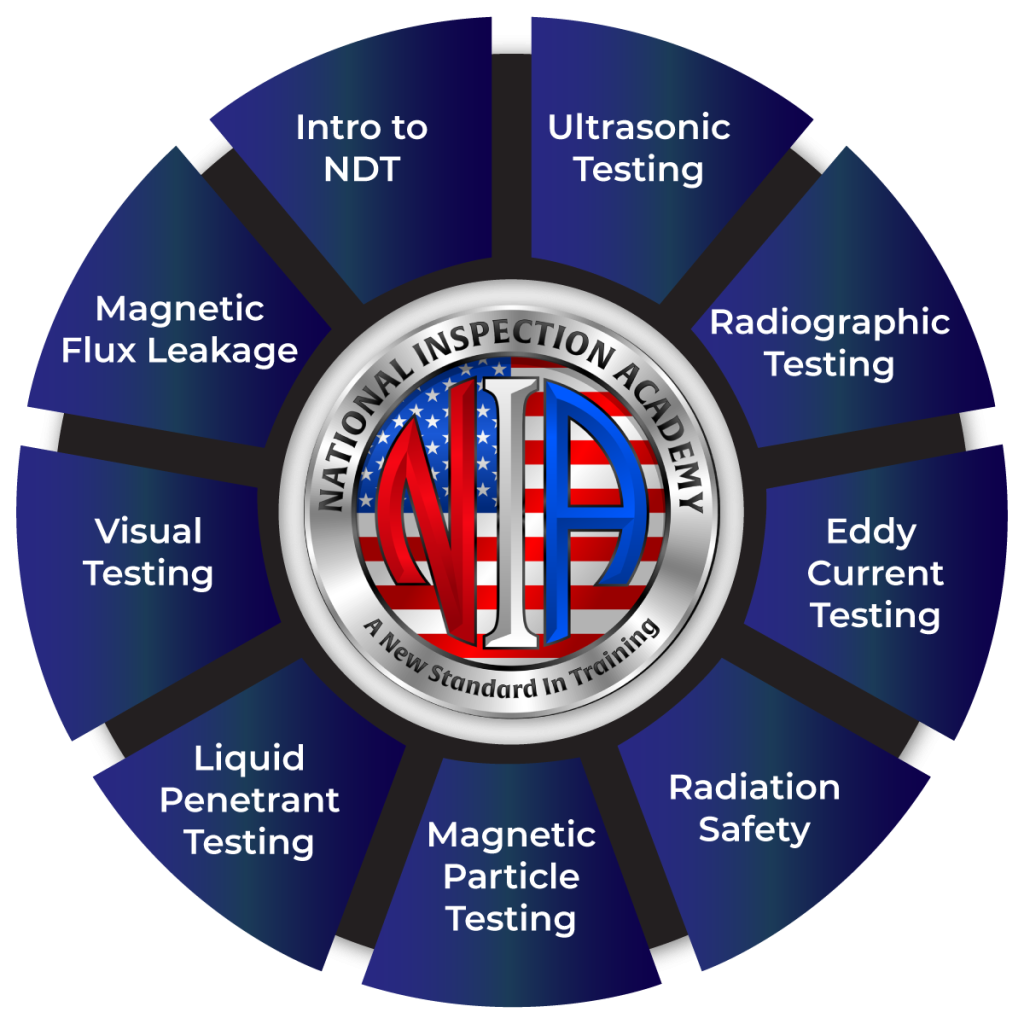

NIA’s NDT Career Program immerses students in the world of NDT, providing them with a robust training program which includes Level I and Level II training in seven highly sought after NDT methods as well as a full radiation safety training course. This level of education propels students into the NDT industry with a diverse training background that employers seek.

Training Format

Our hybrid training program separates the lecture and laboratory training elements into separate components to provide a more flexible learning environment for our students. This approach allows students to continue working full time jobs well enrolled in the NDT Career Program.

Timeline

Students will be expected to complete approximately 400 hours of online training over a six-month period. Students are allowed more time if needed. At the time of enrollment students will be scheduled for the three-week hands-on portion of the training program six months from their online initiation date. The hands on training schedule can be modified to find students needs. Hands-on training will be provided at the NIA facility in Baxter, Minnesota. This provides students ample time to complete the online training portion of the program. Students may request to attend the hands-on portion of the training program in advance of their scheduled date provided that all online training modules are complete, and all exams have been passed.

The hands-on portion of the training program consists of three weeks of Level I and Level II training for all seven NDT methods included in the program. Hands-on classes are from Monday through Friday for three consecutive weeks.

National Inspection Academy has developed a unique NDT Career program that harnesses on demand online training combined with hands on equipment familiarize offers all the education requirements needed to start a career in nondestructive testing. The NDT Career Program consist of level I and level II training in SEVEN inspection methods including a 40-hour radiation safety course. Once the online is complete students will come to our facility in Baxter Minnesota to gain the hands-on experience necessary to start their career. Leading up to graduation we work with students to help them find job placement through out the country that fits their goals.

Facility

NIA facility is a 3,332 square feet facility featuring all necessary inspection equipment for hands-on training. This includes an ultrasonic testing area, X-ray cabinet, subdued lighting areas for magnetic particle testing and liquid penetrant testing, and a film development dark room.

Courses Included

INTRODUCTION TO NDT

This course will give students an introduction to the industry. The course covers the certifications levels and requirements, material processing, and covers the basic principles of the 16 inspection methods that are recognized by the American Society for Nondestructive Testing.

EDDY CURRENT (ECT) LEVEL I

Electromagnetic Testing uses electromagnetic energy either alternating or direct current to yield information regarding the quality and characteristics of the testing material. The ET level I course students will become familiar with the electromagnetic theory, types of eddy current sensing elements, and readout mechanisms. The course will also demonstrate lift off effects, frequency effects, and the effects of scan speed. During the hands-on portion students will become familiar with the equipment and perform the demonstrations themselves.

EDDY CURRENT (ECT) LEVEL II

The ET level II course will begin with a review of electromagnetic theory. The student will learn to understand signal to noise and how to select testing frequencies. Attention will be given to field design considerations and other techniques and applications. The hands-on portion will have students inspecting parts using equipment from the trade. The students will learn the criteria for accepting or rejecting flaws.

INDUSTRIAL RADIOGRAPHY RADIATION SAFETY COURSE

This is a 40-hour industrial radiography course designed to meet or exceed the requirements for certification in radiation safety for both X- and gamma radiography. Students will learn the fundamentals of working safely around radiation emitting sources. Focus will be given to the transportation and storage of radioactive materials. The student will also learn and fully understand the ALARA concept. During the hands-on portion students will learn how to connect the source of radiation used as the emitting device and learn how to calculate barricade distances.

LIQUID PENETRANT TESTING (PT) LEVEL I

NIA Liquid Penetrant Testing Level I course will introduce students to the concepts that make PT. Students will learn the processing, various methods, and equipment used during inspections. The hands-on portion will allow students to become familiar with the process and perform several different types of liquid penetrant inspection.

LIQUID PENETRANT TESTING (PT) LEVEL II

The course will begin with a review of the principles and move into advanced inspection and evaluation or indications. Students will learn how to interpret indications, follow procedures, and other factors affecting indications. The hands-on portion will allow students to follow a work procedure and process parts as if they were employed by an inspection company.

MAGNETIC FLUX LEAKAGE (MFL) LEVEL I

The Magnetic Flux Leakage Level I course will give students all the required information layout in ASNT CP-105. The course will begin with a review of electromagnetic principles. The student will learn how to perform MFL inspections, and the equipment used in the inspection method. The hands-on portion of the course will give students the opportunity to perform calibrations and participate in inspections common in NDT.

MAGNETIC FLUX LEAKAGE (MFL) LEVEL II

The Magnetic Flux Leakage level II course begins with an overview of MFL inspection and the theory of

magnetic fields. Students will learn how to perform MFL inspections while following NIA procedures to

complete MFL reports.

MAGNETIC PARTICLE TESTING (MT) LEVEL I

NIA Magnetic Particle Testing course will give students the knowledge needed to perform (MT) inspections. The course will begin with the theory of magnetic fields and expand into the effect of discontinuities on those magnetic fields. Students will learn how to perform the inspection, follow procedures, and complete reports. The hands-on portion of the course will have students perform MT on test specimens with known defects. Students will be required to complete reports in the classroom as if they were on a job site.

MAGNETIC PARTICLE TESTING (MT) LEVEL II

The MT level II course will start with a review of the principles of magnetic particle testing and go in depth with the types of flux fields that are associated with magnetic particle. The student will learn how to select the proper method for magnetization along with demagnetization procedures. The hands-on portion of this course will have students performing inspections following a set of procedures.

RADIOGRAPHIC TESTING (RT) LEVEL I

The level I radiographic testing course will begin with a review of the physics of radiation and how it interacts with matter. Students will learn the difference between X- and gamma radiation. Once complete the student will be able to calculate the parameters of a quality radiographic exposer. The hands-on portion will have students working in a team as is common within the industry. Students will make exposures and develop exposed film.

RADIOGRAPHIC TESTING (RT) LEVEL II

The level II course will build on the foundation of the level I course and expand into more advanced radiographic principles. The student will learn how to view the radiographic image and be able to interpret discontinuities within the test specimens. The hands-on portion will have students setting up exposures and processing film as if they were on a jobsite in the industry. The student will follow procedures on how to place image quality indicators and sample their images for proper sensitivity levels.

ULTRASONIC TESTING (UT) LEVEL I

The level I Ultrasonic Testing course will begin with an introduction to acoustic principles. The student will learn the basic principles of sound propagation and how the inspection process can locate discontinuities. The student will learn the types of equipment used in the various industries. The hands-on portion will have students performing standardization of the equipment and how to scan the part they are inspecting.

ULTRASONIC TESTING (UT) LEVEL II

This course covers the evaluation of base material through the manufacturing process and will give students and understanding of the discontinuities that can be formed along the way. Students will learn how to detect such discontinuities and will be able to complete reports with their findings. The hands-on portion will have students begin their inspection of specimens with known defects and they must use their knowledge obtained in this course to follow a procedure and interpret signals from the specimen.

VISUAL TESTING LEVEL I

The Visual Testing Level I course begins with the fundamental aspects of visual inspection and the various

equipment used in the inspection process. Students will gain insight into how manufacturing processes can

lead to discontinuities and the specific types of discontinuities that arise at different stages of production.

Through a combination of online and hands-on practice, students will become adept at utilizing various visual

testing (VT) equipment.

VISUAL TESTING LEVEL II

The Visual Testing Level II course offers advanced visual inspection techniques. Students will learn how to use

various inspection gauges used in the inspection industry. This course will also cover the use of rigid

borescopes as well as in-direct borescopes. Students will learn how to detect discontinuities and will be able to

complete reports with their findings follow codes and standards used in visual testing.

REGISTRATION

NIA does not require a registration fee. The $8,000 tuition cost is the only education expense required per student. NIA tuition fee does not cover transportation, lodging or food.

For more information:

Course Completion

Once the online is complete students will come to our facility in Baxter Minnesota to gain the hands-on experience necessary to start their career. Leading up to graduation we work with students to help them find job placement through out the country that fits their goals.