Professional Development Courses (CEU)

Below you will find our Professional Development Continuing Education Courses.

Fundamentals of the Inspection Industry

Credit: 8 hours

Cost: $200

Course Description: Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. There are sixteen different inspection methods used in NDT, seven of the sixteen are the most commonly used. These methods are ultrasonics, radiography, eddy current, liquid penetrant, magnetic particle, visual and magnetic flux leakage. NDT is commonly used in engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering and aeronautical engineering.

Introduction to Visual Testing

Credit: 9 hours

Cost: $200

Course Description: The integrity of most components are verified principally by visual testing. Even for components required to be inspected using other nondestructive testing methods, visual testing is by far the most important NDT method. Therefore, visual testing is of the first order of importance. Many codes and other standards require components to be accepted by visual testing prior to the performance of any other nondestructive testing method. The most extensively used of any method of nondestructive testing method, visual testing is easy to apply, quick, and often requires no special equipment other than good eyesight and some relatively simple and inexpensive tools compared to equipment needed for other NDT methods.

Despite the many advantages of visual testing, a major disadvantage is the need for an experienced inspector who has considerable experience and knowledge in many different areas which encompass visual testing. The VT technician must be familiar with materials, drawings, codes, specifications, weld procedures, performance qualification, procedure qualification requirements, workmanship standards, and all other aspects of good practice in shop and field.

This training program was developed to instruct students on the fundamental basics of Visual Testing principles and theory. Students will be instructed in topics such as fundamentals of vision, lighting and material attributes, use of visual inspection tools and gauges, and visual testing procedures and codes.

Liquid Penetrant Fundamentals

Credit: 4 hours

Cost: $200

Course Description: Liquid penetrant testing (PT) is a sensitive nondestructive testing method for detecting and locating discontinuities which are open to the surface. The NDT method employs a penetrating liquid dye which is applied to the properly cleaned surface to be examined and which enters the discontinuity by capillary action. After a suitable period of time has passed, the excess penetrant is carefully removed from the surface and the part is dried. A developer is then applied which acts as a blotter, drawing the penetrant out of the discontinuity. The penetrant, drawn from an opening on the surface, indicates the presence and location of a discontinuity.

This training program was developed to instruct students on the fundamental basics of Liquid Penetrant Testing principles and theory. Students will be instructed in topics such as principles, types of commercially available liquid penetrants, liquid penetrant processing, test methods and testing equipment.

Magnetic Particle Fundamentals

Credit: 9 hours

Cost: $300

Magnetic Particle Testing (MT) is a nondestructive testing (NDT) method which is used for locating surface or near surface discontinuities in ferromagnetic materials. Magnetic particle testing is based on the principle that magnetic lines of force will be distorted by a change in material continuity; i.e., a discontinuity creating a magnetic field or flux leakage.

A test object is magnetized by passing an electric current through the object (direct magnetization) or by placing it in a magnetic field (indirect magnetization). The electric current creates a magnetic field perpendicular to the current flow. For this reason, magnetic fields are applied in at least two directions, perpendicular to each other, to assure the examination areas are completely evaluated.

When the magnetic field has been established within the test object, magnetic particles are applied to the surface to be examined. They can be dry or suspended in a liquid. Discontinuities can be further enhanced using fluorescent magnetic particles and observing them under black light. After removal of excess particles, the magnetic flux leakage field at a detectable discontinuity reveals its location, shape, and size.

This training program was developed to instruct students on the fundamental basics of Magnetic Particle Testing principles and theory. Students will be instructed in topics such as principles and characteristics of magnetic fields, material discontinuities, magnetization from electric current, selecting methods of magnetization, materials inspection, principles of demagnetization, method testing equipment, discontinuities detected by magnetic particle testing, and MT indications/interpretation.

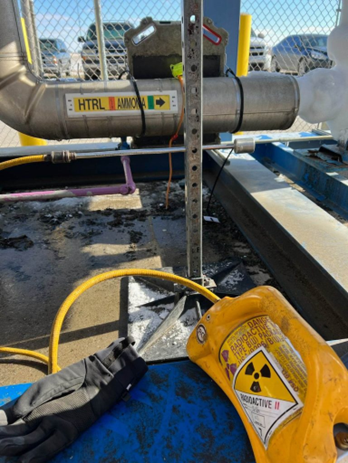

Radiographic Testing Applications

Credit: 7 hours

Cost: $300

Course Description: This training program was developed to instruct students on the fundamental basics of Radiographic Testing principles and theory for conventional film. Students will be instructed in topics such as fundamental physics, radioactive materials, types of radiation, radiations interaction with matter, exposure devices and radiation sources, film types, film development and a review of radiographic safety principles.

Method Description: Radiographic Testing (RT) is a nondestructive testing (NDT) method which utilizes ionizing radiation (X or Gamma Radiation) to penetrate an object and reveal information about its internal conditions. When the test object is exposed to ionizing radiation some of the radiation is attenuated, some of it is scattered, and some passes through the object. The ionizing radiation passing through the test object is detected by a detector. Most radiographic techniques used today employ radiographic film that records a latent image when exposed to ionizing radiation. Other detectors, such as imaging plates, are also used and new radiographic imaging technologies are being developed.

Radiographic Testing Fundamentals

Credit: 7 hours

Cost: $200

Course Description: This training program was developed to instruct students on the advanced theory, and application of radiographic testing. Course content includes topics such as physics review, darkroom facilities, techniques and processing, indications, discontinuities and defects, radiographic film viewing, application techniques, evaluation of castings, evaluation ow welds, and radiography procedures.

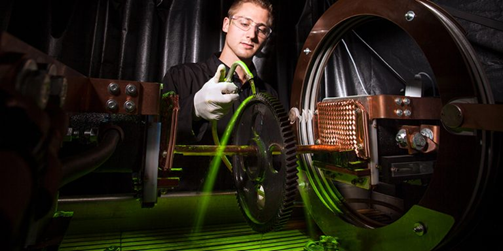

Ultrasonic Testing

Credit: 6 hours

Cost: $200

Course Description: This training program was developed to instruct students in the fundamental theory and principles of ultrasonic testing. Content includes topics such as basic principles of acoustics, equipment, testing methods, calibration straight beam and angle beam examinations to specific procedures.

Method Description: Ultrasonic Testing (UT) is one of the most widely used methods of nondestructive testing (NDT). Its primary application is the detection and characterization of internal discontinuities. It is also used to detect surface discontinuities, to define bond characteristics, and to measure thickness.

High-frequency sound waves are introduced into the material to detect surface and subsurface discontinuities. The sound waves travel through the material with some loss of energy (attenuation) and are reflected at interfaces. The reflected sound beam is detected and analyzed to define the presence and location of discontinuities.

Ultrasonic Testing Applications

Credit: 10 hours

Cost: $300

Course Description: This training program was developed to instruct students on the advanced theory, application, and variables encountered with ultrasonic testing. Content includes topics such as ultrasonic techniques, evaluation of base material product forms, evaluation of welds and bonded structures, discontinuity detection, and evaluation of results.